Refurb at Dublin Airport _ Rapidur® EB5 Rapid Drying Sand Cement screed_B Doherty Screeding

| Job: | Dublin Airport – next phase floor refurb |

| Smet Supported Partner: |

B Doherty Screeding Services |

| Product: | Rapidur® EB5 Rapid Drying Floor Screed |

Related Downloads |

|

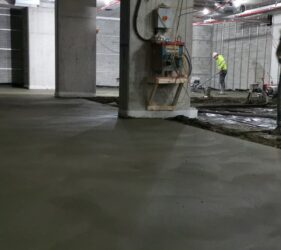

DescriptionUsing their Mobile Screed Factory and in and out in three hours! We supplied our Rapidur® EB5 additive in the next stage of floor refurbishment at Dublin Airport. This was so fast track we started at 7 pm and finished at 10 pm. Our unique Fast Track Screed is a pneumatically pumpable, high-quality, rapid drying, levelling floor screed material based on sand, cement, and Sopro Rapidur® EB5 screed accelerator. This screed is unique in that it allows early use of floor and early final floor covering installations. It’s mixed using Portland Cement, sand, fibres, Sopro Rapidur® EB5 screed accelerator and water. It’s factory-produced on-site by our state-of-the-art mobile screed factory. Our floor screed complies with the requirements of BS EN 13813:2002 and BS 8204: Part 1 and can be used for bonded, unbonded, and floating floor screed constructions for both residential and commercial applications. The hydration process is speeded up through rapid water-binding properties allowing early floor-covering installations. |

|

• Factory Produced On-Site

• Rapid Drying and Fibre Reinforced

• Allowing early use of screed

• Allowing early floor covering installations

• Bonded, Unbonded, and Floating Floor Screed Constructions

• Suitable For Underlayment In Wet Areas

• BS 8204-1 ISCR Categories A, B, and C

SMET delivers another innovative, showcase flooring solution to their Smet Supported Partners. Click the link to see a showcase of jobs recently completed by expert screeder, Brendan Doherty Screeding Services.